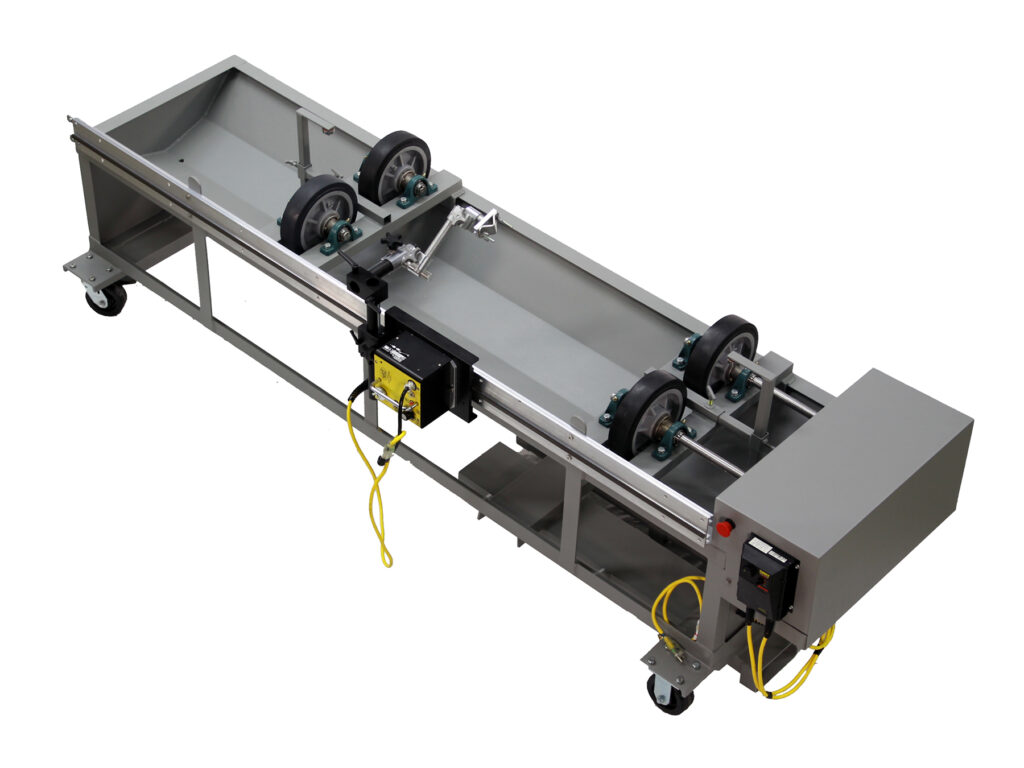

COMPACT & PORTABLE

The Pro-Series’ small footprint means it can go virtually everywhere in your plant you may need it. And with everything contained on a convenient utility cart, you’ll save time and money on production by reducing downtime.

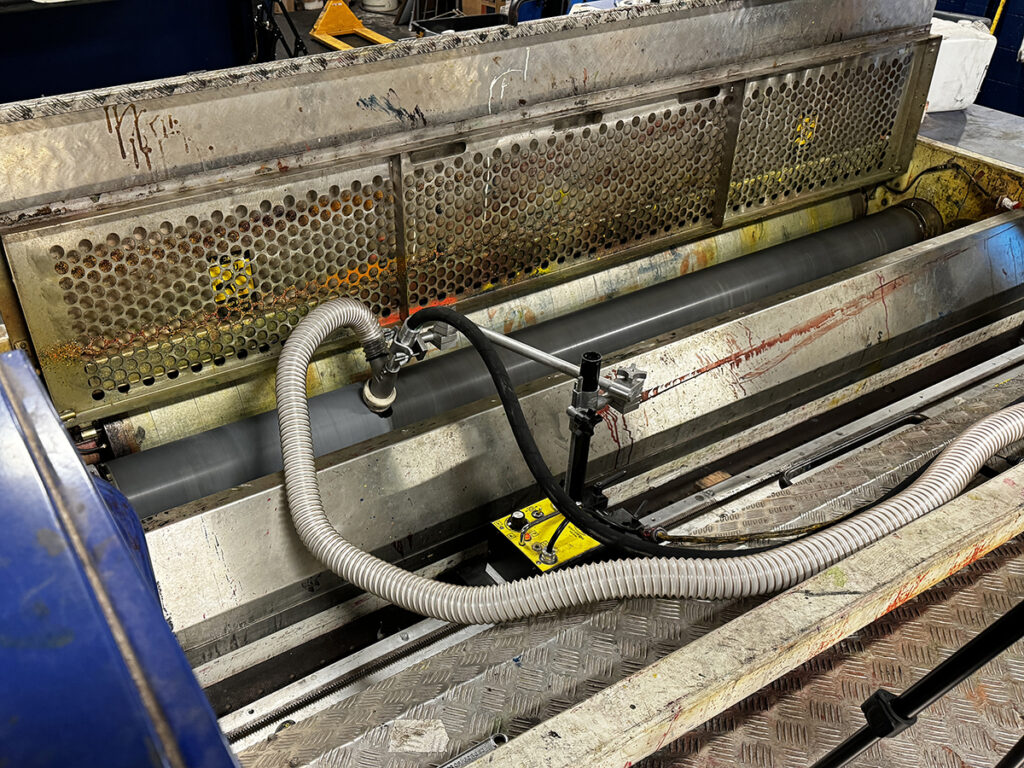

SIMPLE AND EASY-TO-USE

This easy-to-use system only needs one standard electrical circuit and a limited amount of compressed air. It can even connect to your existing quick connect airdrops in most cases!

universal & adaptable

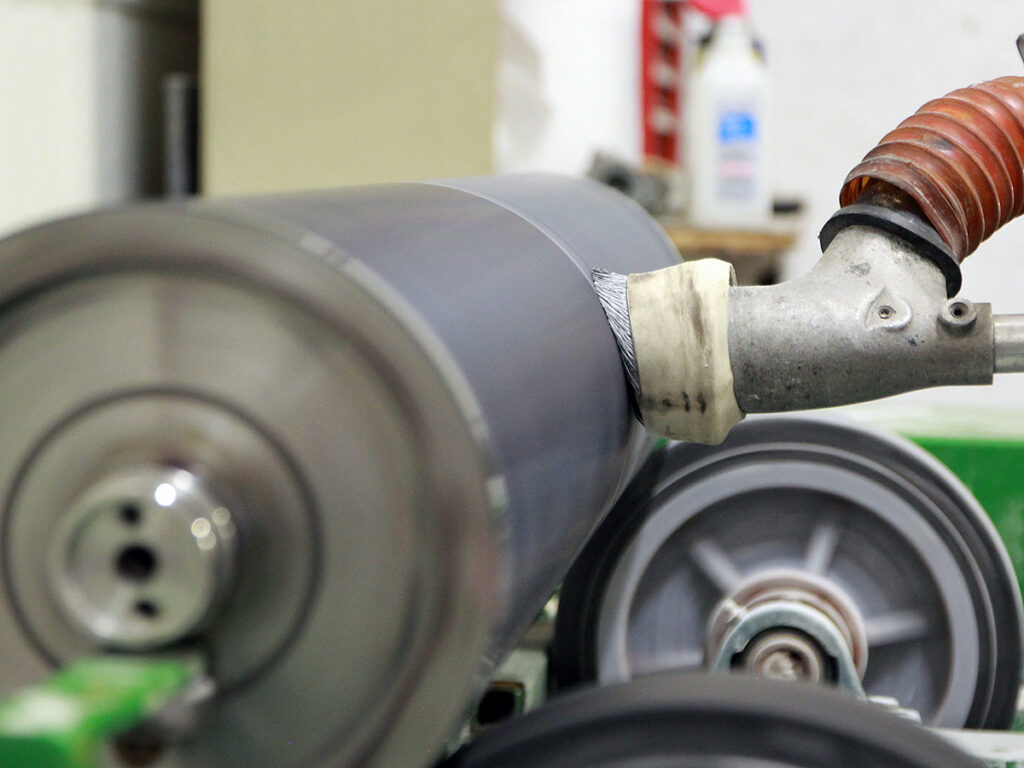

For on-press cleanings, the Pro-Series works on over 25 different presses & counting. It can remove the most stubborn residues on low and high-line screen rolls and high or low volume cells.

Features & ADVANTAGES

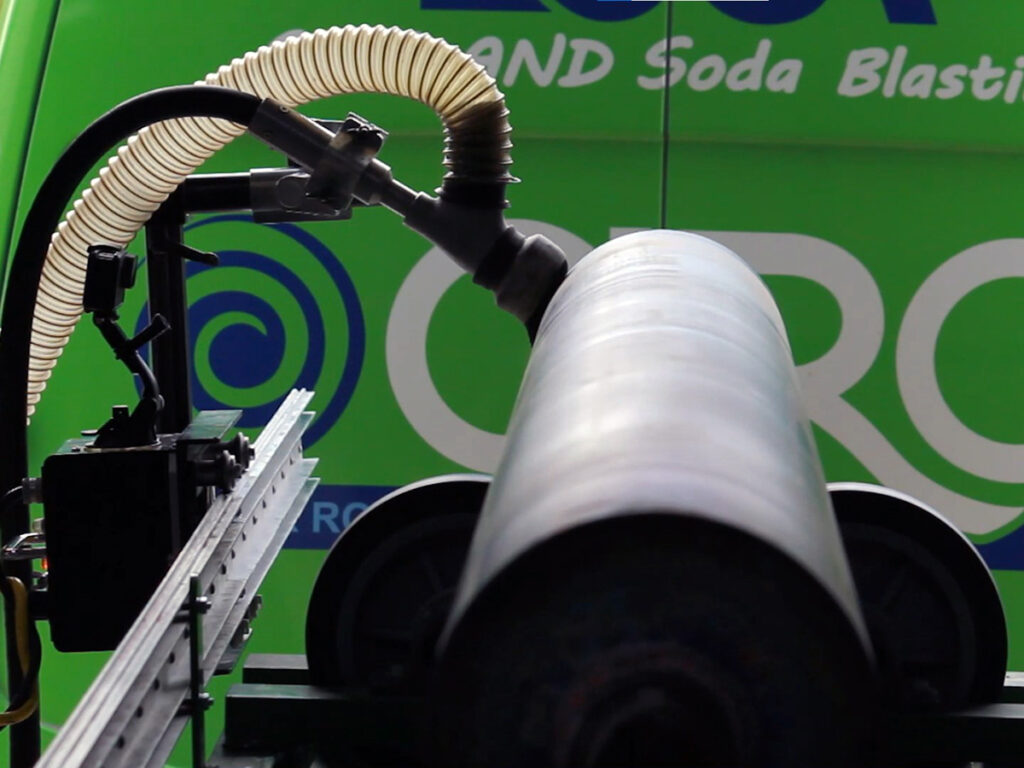

On-Press

For companies with large/jumbo rolls or ones that are very difficult to remove from their press, this is a great option that will save man-hours and downtime. On-press cleaning also reduces the risk of roll damage occurring. Most plants we work with have horror stories about damaged rolls due to mishandling.

Our on-press system is universal and can be used on almost any size roll in any type of press. The equipment is highly portable and designed to be move easily throughout your plant.

OFF-Press