FAST. SAFE. EFFECTIVE.

The best just keeps getting better. Are you looking for the fastest, safest & most effective way to clean your anilox rolls?

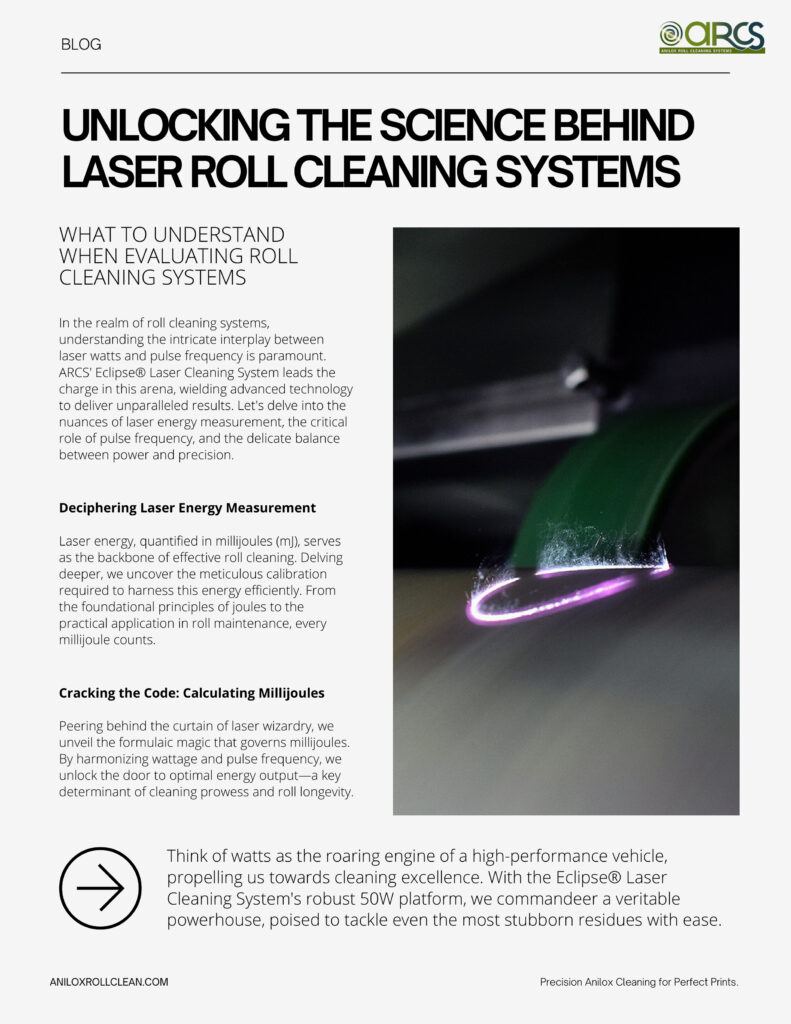

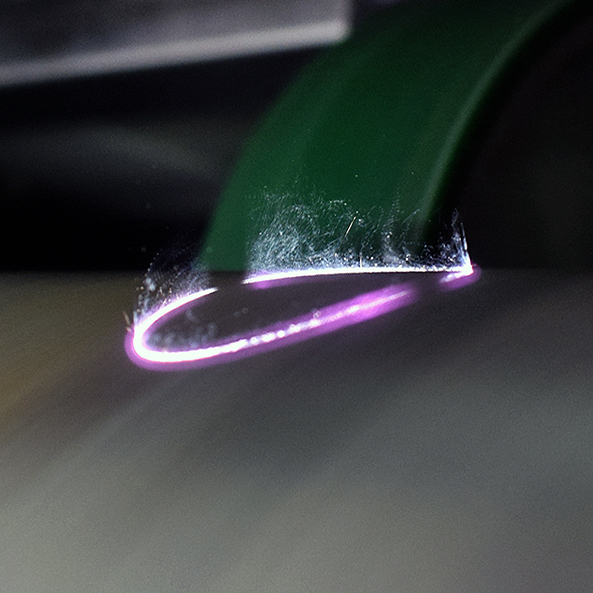

The Eclipse® R2000 Laser System is the fastest anilox cleaning system on the market today. Easily clean any type of ink, coating or residue using our patented circular laser technology that ensures a perfect clean that is safe on your rolls, even after the 1000th cleaning.

CIRCULAR VS. LINEAR

Our circular laser scan technology eliminates even the possibility of hot spot related roll damage that is commonly associated with traditional linear/line scanning systems that are currently on the market.

MADE IN THE USA

Unlike most laser systems on the market today with Chinese-made laser sources, our patented laser system is 100% made right here in the United States, ensuring the highest craftsmanship and support!

FASTER. SAFE. CLEANER.

Our technology removes nearly any type of sticky adhesive, stubborn ink or tough coating off of nearly any type of roll, faster than any other one-head laser system available today!

DID YOU KNOW?

Did you know that our patented circular laser technology is being used in Paris to restore the legendary Notre-Dame Cathedral back to its former glory following the fire that gutted it in 2019? Watch this report to see how our safe & effective laser technology can be used on something as precious as a centuries-old monument.

The same tech has been trusted to clean a 3500 year old Egyptian monolith as well as the legendary marble lions outside the New York City Public Library.

Contact us today to set up your free demo!

- 50 Watt industrial laser – our system design is OSHA compliant and rated as a Class 1 laser which means to laser goggles required.

- Auto-shutoff safety features include interlock feature that will shut the system down if the lid/door is opened or if the roll stops spinning while the cleaning cycle is underway.

- Full enclosed and properly marked & labeled as a laser containing system.

- Physical key switch and password-protected PLC.

- Laser assisted focus

- Laser cleaning speed is about 2-6 inches (51-152 mm) per minute, depending on roll diameter, residue build-up and residue type.

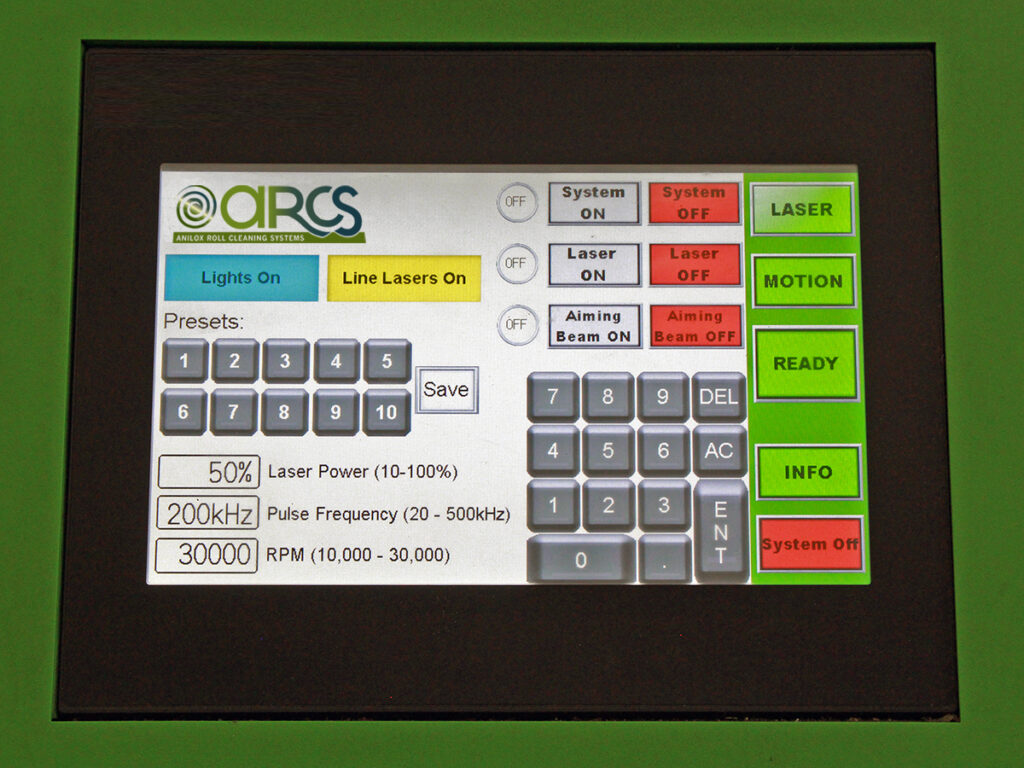

- Easily fine tune parameters by controlling the laser pulse frequency, RPM, scanning speed, roll surface speed and number of cleaning cycles.

- Laser system does not create retained head on roll being cleaning.

- Built-in countdown clock to indicate remaining cleaning time.

- Beacon light and sound indicates cycle start and end times.

- Sensors will indicate if there is an air flow or filter issue.

- Properly-rated real time viewing windows with internal LED lighting.

- Electric requirements = 240V

- Auto-measuring feature for roll length and diameter

- Save individual roll cleaning settings for future use

- System includes USB port for remote access through a laptop for system updates and remote diagnostics