The coatings & lamination industry involves applying protective or decorative coatings onto various substrates like paper, film, or foil, enhancing their durability, appearance, and functionality.

Maximize the performance of your coating and lamination processes with ARCS’s specialized solutions. Our comprehensive range of anilox roll cleaning services, equipment, and liquid cleaners ensures optimal ink transfer and coating uniformity for high-quality results. We understand the unique challenges of coatings and laminations, from viscosity control to surface tension management, and provide tailored solutions to enhance your production efficiency and product quality.

Explore our cutting-edge technologies and industry expertise to overcome common issues such as ink build-up, streaking, and substrate compatibility. With ARCS as your partner, you can achieve precise coating thickness, superior print clarity, and exceptional adhesion for a wide range of applications in coatings and lamination.

Unique Requirements and Challenges:

- Precision and consistency in coating thickness.

- Compatibility with different substrate materials and coatings.

- Minimizing defects such as streaks, bubbles, or uneven application.

- Ensuring adherence to quality and regulatory standards.

Narrow web printing involves high-speed printing on narrow substrates, typically used for labels, tags, and packaging materials.

Optimize your narrow web printing operations with ARCS’s advanced solutions for anilox roll cleaning and maintenance. Our specialized equipment and cleaning processes are specifically designed to meet the needs of narrow web printers, ensuring consistent ink transfer, color accuracy, and print quality. Whether you’re producing labels, flexible packaging, or shrink sleeves, ARCS offers tailored solutions to enhance your printing efficiency and productivity.

Unique Requirements and Challenges:

- Printing on diverse substrates like paper, film, and specialty materials.

- Achieving high-resolution printing with precise registration.

- Managing short print runs and frequent job changes efficiently.

- Addressing challenges like ink adhesion and dot gain.

Wide web printing encompasses large-format printing for applications such as flexible packaging, banners, signage, and industrial materials.

Streamline your wide web printing processes with ARCS’s comprehensive solutions for anilox roll cleaning and maintenance. Our state-of-the-art equipment and proprietary cleaning methods ensure efficient ink transfer, color consistency, and print clarity for a wide range of applications, including flexible packaging, corrugated boxes, and point-of-purchase displays. With ARCS’s industry-leading expertise and innovative technologies, you can optimize your wide web printing operations and achieve superior results.

Unique Requirements and Challenges:

- Printing on wide substrates with consistent color and image quality.

- Managing ink consumption and waste in large-scale production.

- Addressing challenges like ink drying and substrate tension control.

- Ensuring compliance with food safety and regulatory standards.

The corrugated industry involves producing corrugated board used in packaging applications like shipping containers, displays, and point-of-sale materials.

The packaging industry encompasses a wide range of applications, including food packaging, consumer goods packaging, pharmaceutical packaging, and more.

Elevate your packaging printing processes with ARCS’s specialized solutions for anilox roll cleaning and maintenance. Our advanced equipment and proprietary cleaning methods ensure consistent ink transfer, color accuracy, and print clarity for a wide range of packaging applications, including folding cartons, flexible packaging, and rigid containers. With ARCS as your partner, you can optimize your packaging printing operations and deliver high-quality results that meet the strictest industry standards.

Unique Requirements and Challenges:

- Ensuring compliance with regulatory standards and safety requirements.

- Catering to diverse packaging formats, materials, and printing techniques.

- Balancing aesthetics, functionality, and sustainability in packaging design.

- Addressing challenges like barrier properties, product protection, and shelf appeal.

Specialty printing involves producing customized or unique printed materials for specialized applications such as labels, decals, signage, and promotional items.

Achieve exceptional results in specialty printing applications with ARCS’s specialized solutions for anilox roll cleaning and maintenance. Whether you’re printing labels, decals, or specialty packaging, our cutting-edge equipment and cleaning processes ensure precise ink transfer, vibrant colors, and fine detail reproduction. With ARCS as your partner, you can overcome the unique challenges of specialty printing and deliver standout results that captivate your audience.

Unique Requirements and Challenges:

- Catering to diverse customer requirements and design preferences.

- Achieving high-quality printing on unconventional substrates and surfaces.

- Incorporating special effects like metallic inks, varnishes, and embossing.

- Managing short print runs and quick turnaround times.

SERVICES

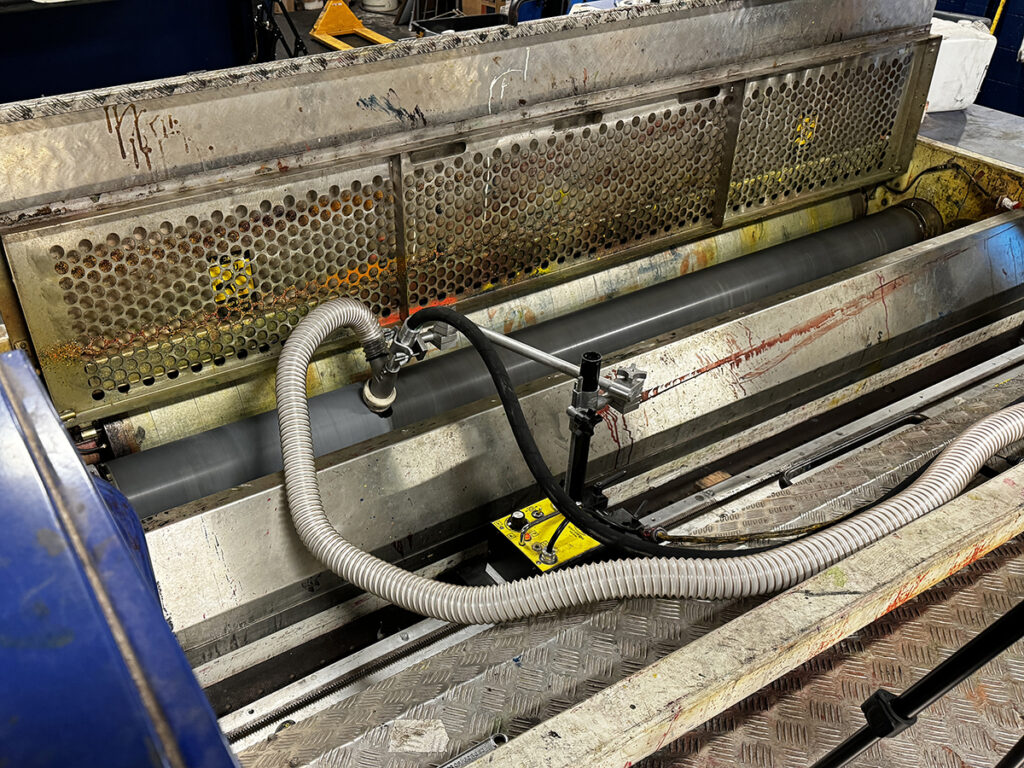

Check out our flexible and comprehensive roll cleaning services for all your anilox maintenance needs. We send a tech to you or you send your rolls to us for a thorough cleaning using our patented Eclipse® laser system or our Pro-Series Soda Blast one.

EQUIPMENT

We proudly offer a full line of anilox roll cleaning system for purchase. Whether you want our safe and effective Eclipse® Laser System or our dust-free Pro-Series Soda Blast System, we have whatever you need for whatever application you may have.

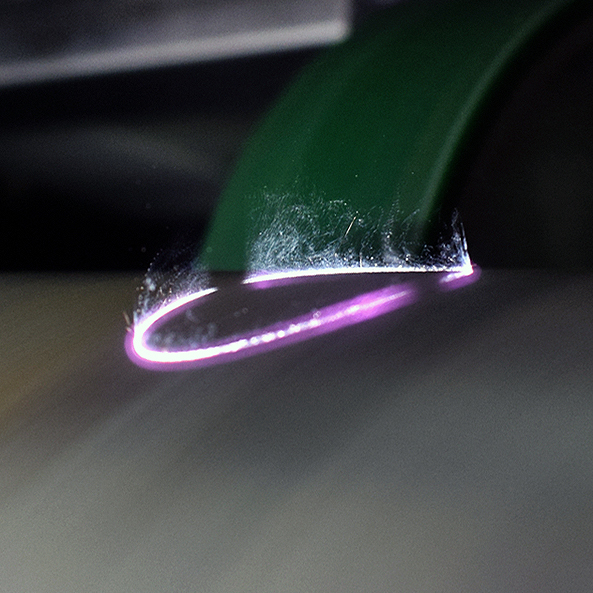

ECLIPSE® LASER

Want to know more about our patented circular laser technology? Click here to learn about the different options, watch a video of the laser in action, see how our laser technology is being used to restore the Notre Dame Cathedral in Paris and more!